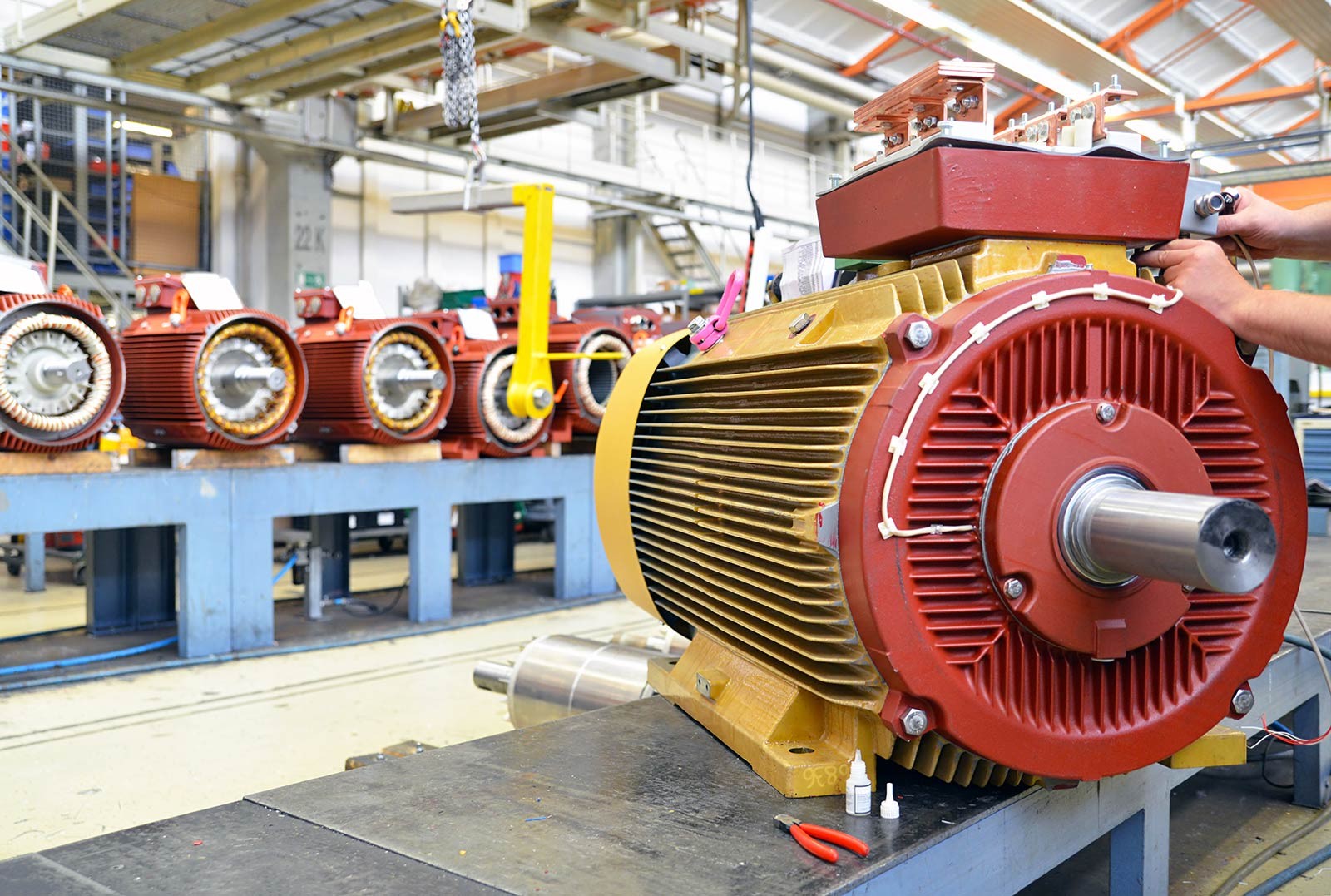

Electric motors are electrical rotary motors that convert electrical energy into mechanical energy that can be utilized to power devices like blowers and fans as well as power equipment. A surplus motor is the ideal choice. The rotor part of a motor consists of steel bars that are linked to induction coils that are powered by the energy source. A commutator can constantly reverse current flow inside its wires.

Buy Electric Motors

Electric motors serve a multitude of industrial applications, from fans and pumps to compressors and power tools. Electric motors account for around 50 percent of all power consumption. Therefore, it is important that when buying one that you spend time to consider and select which model is best suited to your needs and budget needs. Finding the best motor is the best way to ensure that it functions efficiently, effectively and safely for you.

Price considerations when purchasing electric motors are contingent on the composition of its materials, as well as the manufacturer's reliability and specifications. Motors constructed using pure copper typically cost more when compared with motors constructed using other materials, however the additional cost will pay dividends over time in relation to performance and durability.

The efficiency of energy use is yet another factor that can affect the cost in electric motors. Motors built with more energy-efficient designs could reduce operational costs in the long run by turning more electrical energy they generate into mechanical energy. It can also help save your business cash over time. Though the initial investment might be greater, the energy saving features can result in long-term savings for your company.

When buying an electric drive designed for industrial use, be sure to be aware of its dimensions and its type. The power, the voltage and current are all crucial in the speed and torque ratings; depending upon your particular requirements, the motor may come with built-in thermal overload protection devices.

Used Electric Motors

Electric motors play an important function in the industrial equipment Therefore, maintaining them effectively is necessary to ensure proper operation and savings. This is especially important for more powerful electric motors found in diverse industries. This could result in significant financial loss if they malfunction.

To ensure that buy electric motors, its vital to oil their bearings and brushes regularly with oil. This helps reduce friction and prolongs the life of their motors. Additionally, the manufacturers suggest following an exact schedule of applying oil to the motor's windings. Additionally, it is recommended to regularly check in the event of signs of heat loss or short circuiting.

The excessive vibration could lead to an early breakdown of motors. This can result of misalignment or corrosion; to decrease the vibration level at levels that are stable and even, it is crucial that regular checks with vibration measuring tools are conducted; regular check-ups using one will identify any potential cause and rectify it.

Writing down the procedures for maintenance and tests carried out on motors powered by electricity will be essential for repairs or troubleshooting in the future, and using dielectric-tested test equipment during maintenance is recommended to protect yourself. In addition, gloves can provide necessary extra safeguards during work tasks for maintenance.

Surplus Motors

No matter what motor you need to replace or you require for commercial use, sometimes the best solution isn't to buy a new one instead, but buying surplus. By doing this, you can save money and reduce wait times in the event of purchasing brand new.

Surplus motors may be found in quality from "as-is" to "E-OK," or be fully renovated; however, their cost could increase as more work is carried out on them. Nevertheless, there remain many compelling arguments for purchasing used surplus electric motors.

Purchase of surplus electric motors is both more cost-effective and environmentally-friendly. Electric motors manufacturing consumes a lot of energy; by purchasing surplus motors you are helping cut carbon emissions as well as cutting down on greenhouse gas emissions.

Another advantage of buying surplus motors is that they are usually available faster than brand new ones, especially if reconditioned by a reliable company that guarantees the quality and reliability of their work. Therefore, businesses looking for repairs that are quick or upgrade are likely to find these motors advantageous.

Industrial Electric Motors

Industrial electric motors convert electrical energy to mechanical power that is used for the operation of machinery, equipment and automated processes. They can be powered directly by batteries or using AC electric power generated by a grid or inverter source or fuelled using internal combustion engines. However, the main use for them is in machinery driving and equipment operation.

Manufacturers design industrial electric motors in various sizes, shapes, and models specifically for use in specific areas. Examples of this include AC induction motors including squirrel cage and wound rotor motors. They use electromagnetism that spins their rotating stator. Some other types of popular models are DC brushless and brushed motors. There are also AC Asynchronous as well as DC asynchronous models. buy electric motor from surplusrecord industrial electrical motors. They're the best buy of electric motor utilized electric motors for sale on surplusrecord.

Be aware of more than a motor's specifications as well as its capabilities in deciding on the best type. Consider its frequency, time, speed range, and torque demands as also environmental factors like temperature and dirt, or any other conditions which could arise from use.

Staying current with industry developments and best practices will help make motor-driven systems more efficient. A few nations are currently converting the Energy Performance Ladder standards for industrial motors to 200kW or more up to IE4 levels by 2023. providing significant savings by the early replacement of motors, variable speed drives, improved controls and system optimisation that can help reduce increase in demand for electricity and decrease the cost of energy.